n costs due to the need for expensive hardware and software.

What is the main difference between CAD and CAM

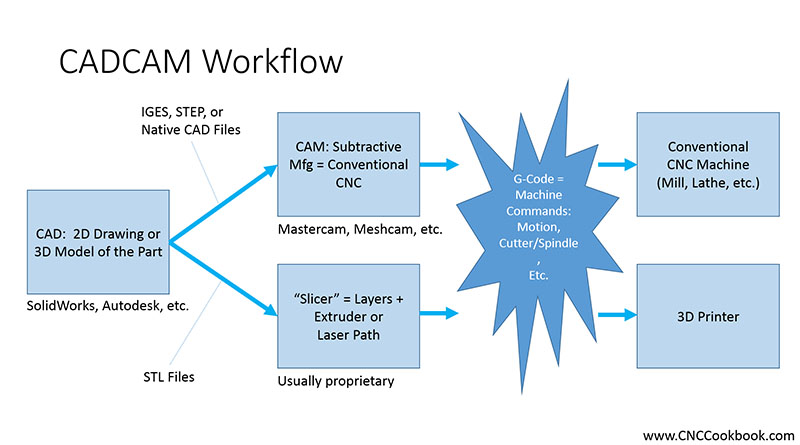

CAD is the use of computers in order to develop, modify and analyse the design. CAM is the use of computer software in order to handle machine tools used in the manufacturing of modules. It is also called Computer-Aided Drafting. It is also called Computer-Aided Modelling.

What are 2 disadvantages of CAD and CAM

Disadvantages of CAD/CAM

CAD/CAM software consumes a lot of PC processing power. Its quality processing components are also costly. CAD requires modern production components that are very expensive, and as such may be uneconomical for smaller firms.

What are two advantages of CAD and CAM

CAD-CAM engineering software allows us to integrate directly with the CNC turning and milling plant. The close integration of the design and manufacturing process helps reduce the gap between the two processes. It also allows the machines to be used in the most efficient way.

What are the disadvantages of CAM CAD

Disadvantages of CAMComputer errors are possible.CAD and CAM software can be expensive.Training is expensive.Computers and controllers to run the software and CNC machinery for manufacturing is expensive.

Is Solidworks a CAM or CAD

SOLIDWORKS CAM is an add-on to all versions of SOLIDWORKS CAD that lets you prepare your designs for manufacturability earlier in the development cycle.

What is the advantage and disadvantage of CAD

CAD has specific tools to measure the skill, precision and accuracy level of a design, thereby giving you an improved level of accuracy. Re-use code: By using the CAD software, you can copy different parts of the code and design, which you can reuse over and over again for several other designs.

What are the pros and cons of CAM

Computer aided manufacture (CAM)

| Advantages of CAM | Disadvantages of CAM |

|---|---|

| Machines can run constantly on repetitive tasks | Needs a skilled workforce of engineers |

| Good for producing on a mass/flow production line | Downtime required for maintenance |

| Less material wastage | Computers and machines can fail |

What are 5 disadvantages of CAD

Disadvantages of CAD:Work can be lost because of the sudden breakdown of computers.Work is prone to viruses.Work could be easily “hacked”Time taking process to know how to operate or run the software.High production or purchasing cost for new systems.Time and cost of training the staff which will work on it.

What are 3 disadvantages of CAD

Disadvantages of CAD:Work can be lost because of the sudden breakdown of computers.Work is prone to viruses.Work could be easily “hacked”Time taking process to know how to operate or run the software.High production or purchasing cost for new systems.Time and cost of training the staff which will work on it.

Do companies use AutoCAD or SOLIDWORKS

Both design software packages have their strengths: SOLIDWORKS is more powerful for mechanical design, while AutoCAD is more versatile for early-stage design. This is why you'll find that the same design companies–and even the same people–use both AutoCAD and SOLIDWORKS.

Why use SOLIDWORKS instead of AutoCAD

Solidworks offers more fully developed 3D modeling tools than AutoCAD, and the Solidworks features are easier to use. It also has a vibrant, engaged user community that can provide help to beginners.

What are 5 advantages of CAM

The benefits of CAMGreater speed in producing components.Greater accuracy and consistency, with each component or finished product exactly the same.Greater efficiency as computer controlled machines do not need to take breaks.High sophistication in terms of following complex patterns like tracks on circuit boards.

What are 3 advantages of CAD

CAD allows experts to create more accurate design representations. CAD replaced manual design drafting, allowing design development, alteration and optimization. CAD enables engineers to craft more precise designs and manipulate them virtually. CAD software calculates how multiple materials relate.

What is a disadvantage of CAM

Disadvantages of CAM are: Requires specialist training. Software and machinery costs are expensive. Workers could potentially loose employment due to machines replacing them.

What CAD software do most engineers use

AutoCAD

AutoCAD is the most widely used CAD software in the world. The software allows users to build 2D and 3D drawings, maps, and models. It is a great tool for architects, engineers, and construction professionals.

Which is harder AutoCAD or SOLIDWORKS

Learning Curve for AutoCAD and Solidworks

AutoCAD is best suited to 2D drafting and is therefore easier to master. The 3D modeling in Solidworks adds another dimension to becoming proficient with the software.

Do professionals use Solidworks

When the dimensions are modified, the 3D model changes its shape. SolidWorks has powerful tools, including Simulation, the ability to draw using either parts or assemblies, Rendering tools, and others. SolidWorks is used by engineers and professionals, and is also taught at mechanical and engineering schools.

Do engineers use solidworks or AutoCAD

Which industry

| Industry | Preferred Software |

|---|---|

| Civil and structural engineering | AutoCAD |

| Mechanical and industrial engineering | Either, depending on toolkit needs |

| Electronic, electrical and technology design | SolidWorks |

| Mechanical parts and assembly design | SolidWorks |

What are the advantages and disadvantages of CAD and CAM

Advantages And Disadvantages Of CAD CAMAdvantage: Application Flexibility:-Advantage: Design Flexibility:-Advantage: Automated Specification Checking.Disadvantage: Handling Energy Restrictions and Cost.Disadvantage: Application Complexity.

What CAD system does Tesla use

Tesla has a wide range of CAD software that they rely on to design, test, and manufacture their products. From Autodesk Inventor and Solidworks for mechanical design, to Catia and Siemens NX for complex designs, Tesla uses the best CAD software available to bring its cutting-edge technology into the world.

What CAD software does NASA use

It is the use of a computer to make designs of real objects more efficient for building and function. NASA uses several CAD software packages. They use CATIA, Unigraphics and CADDS. CATIA is especially effective at designing more advanced spacecraft, as opposed to satelites.

Do engineers use SOLIDWORKS or AutoCAD

Which industry

| Industry | Preferred Software |

|---|---|

| Civil and structural engineering | AutoCAD |

| Mechanical and industrial engineering | Either, depending on toolkit needs |

| Electronic, electrical and technology design | SolidWorks |

| Mechanical parts and assembly design | SolidWorks |

What is the highest salary of SOLIDWORKS

SolidWorks Designer Salaries

| Job Title | Salary |

|---|---|

| SolidWorks Designer salaries – 1 salaries reported | ₹35,875/mo |

| SolidWorks Designer salaries – 1 salaries reported | ₹25,584/mo |

| Solidworks Design Engineer salaries – 1 salaries reported | ₹30,000/mo |

| Solidworks Design Engineer salaries – 1 salaries reported | ₹20,817/mo |

Is SOLIDWORKS being phased out

DS announced the phasing out of SOLIDWORKS online licensing. SOLIDWORKS 2022 does not offer this licensing methodology, and it will stop working for prior versions in February of 2022. However, this change does not mean that the benefits of using SOLIDWORKS anywhere have to be abandoned!

Should I learn CAD or SOLIDWORKS

Of the two, AutoCAD is undeniably the choice for architecture. If you need 2D diagrams explaining how a system works, similar to what you see in a textbook, AutoCAD is also the better choice. If you intend to 3D print, use beams, or need 3D model renders, SolidWorks is the way to go.