Summary of the Article:

Visual inspection is a technique for detecting defects using the naked eye to ensure equipment is working properly or that manufactured products are being made to specification. This can include visual inspections done in person or remotely using digital images.

Machine vision systems for inspection are used to detect defects, contaminants, functional flaws, and other irregularities in manufactured products. Examples include inspecting tablets of medicine for flaws, displays to verify icons or confirm pixel presence, or touch screens to measure the level of backlight contrast.

The typical range of a modern machine vision system can be between 5000 to 20000 USD. This includes hardware costs, software costs, computation costs, and storage costs.

A vision system is a type of technology that enables computers to interpret visual data, essentially enabling them to see. It uses various algorithms and techniques to analyze images and videos in order to extract useful information, such as object recognition, tracking, and measurement.

Borescope is a visual inspection tool that allows inspectors to see areas that are otherwise inaccessible. Video and digital microscopes magnify images using digital technology.

The three most common types of quality inspections are pre-production inspection, during production inspection, and final random inspection.

A well-achieved visual inspection provides a reduction in the amount of repairs to the weld, leading to greater production of the other non-destructive tests and therefore decreasing the cost of production.

The different types of vision systems include 1D Vision Systems, 2D Vision Systems, Line Scan or Area Scans, and 3D Vision Systems.

Questions:

- What is a visual inspection system?

- What is the use of vision inspection system?

- How much does a vision inspection system cost?

- What is a vision system in information system?

- What tool is used for visual inspection?

- What are 3 types of inspection?

- What are the benefits of visual inspection?

- What are the different types of vision inspection?

Visual inspection is a technique for detecting defects using the naked eye to ensure equipment is working properly or that manufactured products are being made to specification. This can include visual inspections done in person or remotely using digital images.

Machine vision systems for inspection are used to detect defects, contaminants, functional flaws, and other irregularities in manufactured products. Examples include inspecting tablets of medicine for flaws, displays to verify icons or confirm pixel presence, or touch screens to measure the level of backlight contrast.

The typical range of a modern machine vision system can be between 5000 to 20000 USD. This includes hardware costs, software costs, computation costs, and storage costs.

A vision system is a type of technology that enables computers to interpret visual data, essentially enabling them to see. It uses various algorithms and techniques to analyze images and videos in order to extract useful information, such as object recognition, tracking, and measurement.

A borescope is a visual inspection tool that consists of a tube with an eyepiece at one end and a lens at the other. Borescopes allow inspectors to see areas that are otherwise inaccessible. Video and digital microscopes magnify images using digital technology.

The three most common types of quality inspections are pre-production inspection, during production inspection, and final random inspection.

A well-achieved visual inspection provides a reduction in the amount of repairs to the weld, leading to greater production of the other non-destructive tests and therefore decreasing the cost of production.

Broadly speaking, the different types of vision systems include 1D Vision Systems, 2D Vision Systems, Line Scan or Area Scans, and 3D Vision Systems.

What is a visual inspection system

Visual inspection is a technique for detecting defects using the naked eye to ensure equipment is working properly or that manufactured products are being made to specification. This can include visual inspections done in person or remotely using digital images.

What is the use of vision inspection system

A machine vision system for inspection detects defects, contaminants, functional flaws, and other irregularities in manufactured products. Examples include inspecting tablets of medicine for flaws, displays to verify icons or confirm pixel presence, or touch screens to measure the level of backlight contrast.

Cached

How much does a vision inspection system cost

The typical range of a modern machine vision system can be between 5000 to 20000 USD. This includes hardware costs, software costs, computation costs, and storage costs.

What is a vision system in information system

A vision system is a type of technology that enables computers to interpret visual data, essentially enables them to see. It is a complex system that uses various algorithms and techniques to analyze images and videos in order to extract useful information, such as object recognition, tracking, and measurement.

What tool is used for visual inspection

A borescope is a visual inspection tool that consists of a tube with an eyepiece at one end and a lens at the other. Borescopes allow inspectors to see areas that are otherwise inaccessible (see picture below). Video and digital microscopes. Video and digital microscopes magnify images using digital technology.

What are 3 types of inspection

As you can see below.The three most common types of quality inspections.Pre-Production Inspection.During Production Inspection.Final Random Inspection.

What are the benefits of visual inspection

A well-achieved visual inspection provides a reduction in the amount of repairs to the weld, leading to greater production of the other non-destructive tests and therefore decreasing the cost of production.

What are the different types of vision inspection

Broadly speaking the different types of vision systems include 1D Vision Systems, 2D Vision Systems, Line Scan or Area Scans and 3D Vision Systems.

How accurate are vision systems

01" or . 001". One half of each step is thus equal to 0.0005". In other words, the accuracy of the machine vision system should be equal to or better than 0.0005".

What is the success rate of visual inspection

Juran, one of the giants of Quality, has written that, based on his studies performed on Inspector accuracy, 100% inspection is about 87% effective.

What is an example of vision system

Important examples are the automatic assembly of car tyres, identification of rear axles for spray painting by robots, are welding process control and the pattern correct sewing of textiles.

What are the main components of a vision system

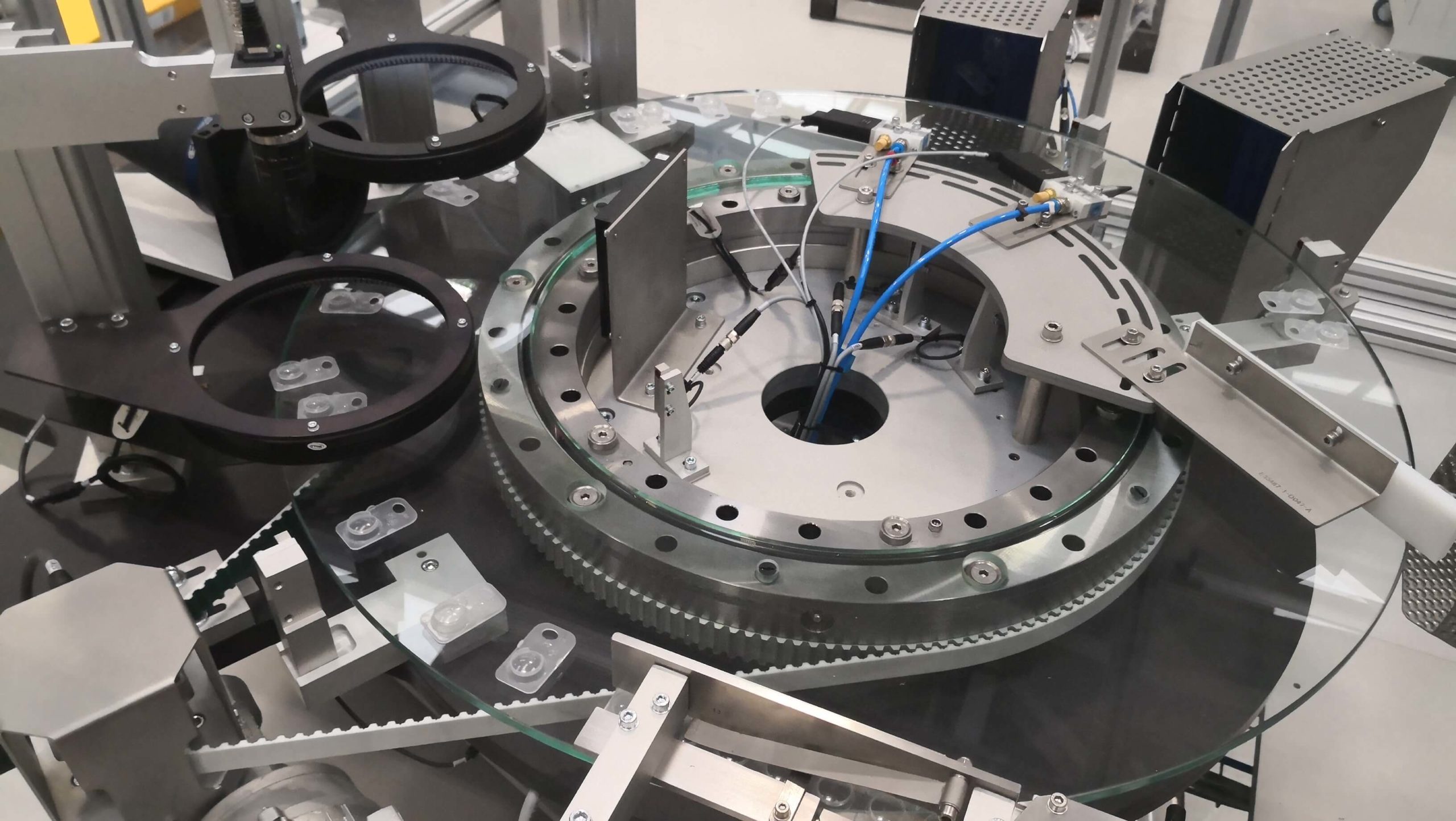

The major components of a machine vision system include the lighting, lens, image sensor, vision processing, and communications.

What is the standard for visual inspection

Policy: Visual Inspection Standards (VIS) provide relaxations from the surface condition (normally flawless) implied by engineering drawings. Only those relaxations (called imperfections) allowed by this VIS, or the engineering drawing are permitted on parts to which this VIS is assigned.

How many types of visual inspection are there

These include digital cameras, borescopes, videoscopes, video and digital microscopes, and closed-circuit surveillance television. Remote visual inspection (RVI) tools like drones and robots allow inspectors to collect visual data without the need to be physically present in the site being evaluated.

What are the five 5 types of inspection

Types of inspection and methods of quality control inspections differ for a reason so it's good to know the details.Sample Checking.Pre-Production Inspections (PPI)During Production Inspection (DPI)Pre-Shipment Inspection (PSI)Piece by Piece Inspection (or Sorting Inspection)Metal Detection.

What are the 4 types of inspection

In quality control, there are 4 types of quality inspections, namely: pre-production inspection, during production inspection, pre-shipment inspection, and container loading/unloading inspections. Each of these types of inspection has its own purpose.

What is an example of a visual inspection

Examples of such inspections include the detection of misshapen or slightly bent electronic parts, the detection of chipped or incomplete resin molded products or include foreign matter, and the detection of package-label mistakes.

What are the requirements of visual inspection

Quality inspectors should use this checklist to effectively:Indicate product ID and location.Capture photo evidence of products and/or defects.Determine pass/fail decisions based on a reference image.Identify visual defects based on defect criteria.Complete the visual inspection with a digital signature.

What is the difference between vision system and vision sensor

The difference between vision sensors and vision systems is fairly basic: A vision sensor does simple inspections like answering a simple yes-no question on a production line. A vision system does something complex like helping a robot arm weld parts together in an automated factory.

Can a vision test be wrong

Errors can occur during your eye examination, where the optometrist interpretes your answers about what you can and can't see. If you scheduled your eye exam after work, when your eyes are tired and strained, it could skew the results of the exam.

Do you start cleaning with a visual inspection

A visual inspection should be performed after a completed cleaning operation. At the same time, this is often not part of the documentation and can result in questions about conducting the visual inspection conducted in the event a cleaning cycle is aborted.

What are the different types of vision inspection systems

Choosing the right vision system is essential to meeting the needs of your specific vision applications. Broadly speaking the different types of vision systems include 1D Vision Systems, 2D Vision Systems, Line Scan or Area Scans and 3D Vision Systems.

What are four common uses of vision systems

The technology and methods can be used for various applications from being able to identify defects, provide product sortation, barcode reading, end-of-line vehicle inspection, product checking, and robotic production, just to name a few.

What is the difference between optical inspection and visual inspection

Beyond the Naked Eye

In those cases, optical inspection is actually metrology because it provides quantifiable measurements from the image. Unaided inspection by the eye is usually called visual inspection. When a lens or lens system is introduced, visual inspection becomes optical inspection.

What are the 3 inspection types

As you can see below.The three most common types of quality inspections.Pre-Production Inspection.During Production Inspection.Final Random Inspection.