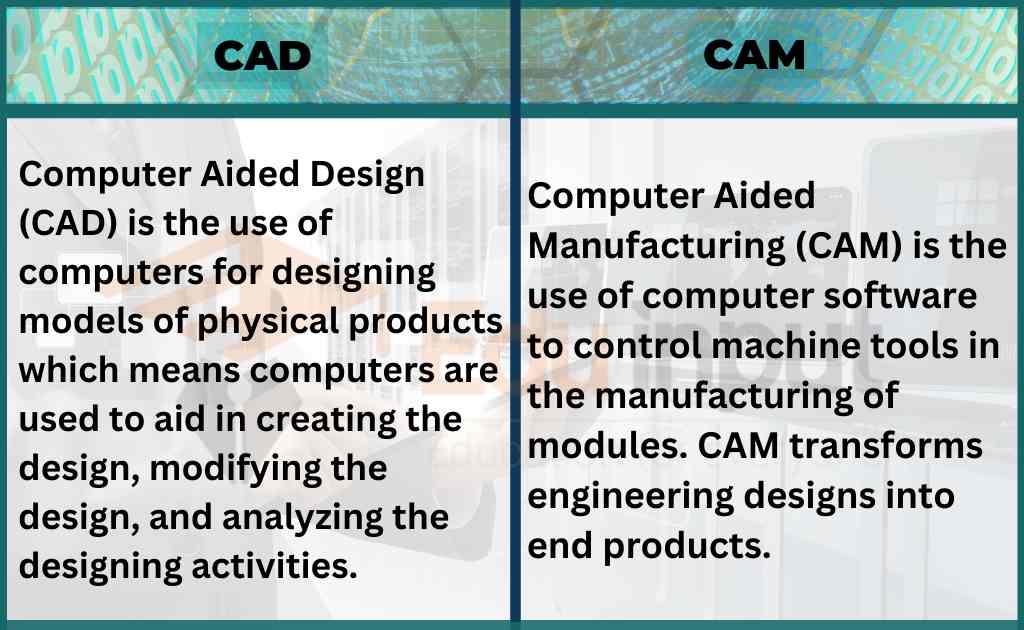

e what to do, Computer-aided design (CAD) software to create the digital model of the product, and Computer-aided machining (CAM) software to generate the toolpath instructions for the machine.

CAM is used for a variety of manufacturing processes, including milling, turning, drilling, and more. It is commonly used in industries such as automotive, aerospace, and electronics to automate the production process and increase efficiency.

One advantage of using CAD and CAM is the ability to simulate and optimize the manufacturing process before actually producing the physical product. This helps to reduce errors, identify potential issues, and improve overall production quality.

Another advantage is the ability to automate repetitive tasks and increase productivity. With CAM software, manufacturers can program the machine to perform complex operations with precision and speed, which is not possible with manual processes.

However, there are also disadvantages to using CAD and CAM. One disadvantage is the high cost of the software and hardware required. CAD/CAM systems require powerful computers and specialized equipment, which can be expensive to acquire and maintain.

Another disadvantage is the learning curve associated with using CAD and CAM software. It takes time and training to become proficient in using the software and understanding the intricacies of the manufacturing process.

In conclusion, CAD and CAM are essential tools for modern manufacturing. They allow manufacturers to design and produce complex products with efficiency and precision. Although there are disadvantages, the benefits of using CAD and CAM outweigh the drawbacks for many industries.

Why is CAD better than CAM

CAD provides the information-dense digital models that a CAM system needs to program manufacturing. CAM writes intuitive G-code that in turn makes CAD models real. In the best-case scenario, the CAD and CAM software systems can interconnect seamlessly, with no lost data or glitches.

Cached

What is relationship between CAD and CAM

Computer Aided Manufacturing:

A CAM tool uses a product model created in CAD software. The former converts the computer models into a language understood by the machining tool and undertakes the production. CAM can also help manufacturers with product planning, development, management, storage, and logistics.

What is the difference between CAM and CAD and CAE

The last letter for CAD, is Design, for CAE, is Engineering, and for CAM, is Manufacturing. These are engineering and manufacturing software programs. Each one is has its own purpose. The article will dive into a high-level look at all three systems and how they are used and their overall purpose.

Cached

What is the difference between CNC and CAD

Turns out CNC means computer numerical control, CAD means computer-aided design, and CAM means computer-aided machining. One process the CNC machine utilizes is a subtractive manufacturing process.

What are 2 disadvantages of CAD and CAM

Disadvantages of CAD/CAM

CAD/CAM software consumes a lot of PC processing power. Its quality processing components are also costly. CAD requires modern production components that are very expensive, and as such may be uneconomical for smaller firms.

Is Solidworks a CAM or CAD

SOLIDWORKS CAM is an add-on to all versions of SOLIDWORKS CAD that lets you prepare your designs for manufacturability earlier in the development cycle.

Why do people use CAD and CAM

The CAD-CAM software allows manufacturers to receive CAD files from their customers. After receiving these files, they can set up the machining tool path, and perform simulations, which helps them calculate the machining cycle times.

What is CAM used for

Computer Aided Manufacturing (CAM) is the use of software and computer-controlled machinery to automate a manufacturing process. Based on that definition, you need three components for a CAM system to function: Software that tells a machine how to make a product by generating toolpaths.

Is CAM used for CAD

CAD/CAM refers to the integration of Computer-aided design (CAD) and Computer-aided manufacturing (CAM). CAD/CAM software is used to design and manufacture prototypes, finished products, and production runs of products using a single development tool.

Which is better CAD or CAM

CAD is used for creating 2D and 3D drawings and models. CAM is to design machining processes through 3D models. It is usually preferred by engineers.

Are CAM and CNC the same

Today, computer-aided manufacturing, abbreviated as CAM, is widely used as part of automating a manufacturing process. CAM is one of the important aspects of computer numerical control (CNC) machining.

What are 5 advantages of CAM

The benefits of CAMGreater speed in producing components.Greater accuracy and consistency, with each component or finished product exactly the same.Greater efficiency as computer controlled machines do not need to take breaks.High sophistication in terms of following complex patterns like tracks on circuit boards.

What are the pros and cons of CAM

Computer aided manufacture (CAM)

| Advantages of CAM | Disadvantages of CAM |

|---|---|

| Machines can run constantly on repetitive tasks | Needs a skilled workforce of engineers |

| Good for producing on a mass/flow production line | Downtime required for maintenance |

| Less material wastage | Computers and machines can fail |

Is AutoCAD a CAM software

CAD and CAM are different. CAD helps designers create digital representations called 3D models while CAM helps write code to drive CNC machines that create physical parts.

Is AutoCAD a CAD CAM software

CAD stands for Computer-Aided Design and CAM stands for Computer-Aided Manufacturing, both of which are used to make things. CAD/CAM software is used to design and manufacture prototypes, finished products and production runs of products.

What are 3 disadvantages of CAM

Disadvantages of CAM are:Requires specialist training.Software and machinery costs are expensive.Workers could potentially loose employment due to machines replacing them.

What is an example of CAD and CAM

Examples of CAD software include AutoCAD, Autodesk Inventor, CATIA, and Solid Works. Examples of CAM software include Work NC, Siemens NX, Power MILL, and Solid CAM.

What are 3 benefits of CAM

The benefits of CAMGreater speed in producing components.Greater accuracy and consistency, with each component or finished product exactly the same.Greater efficiency as computer controlled machines do not need to take breaks.High sophistication in terms of following complex patterns like tracks on circuit boards.

What is an advantage of using CAM

Computer aided manufacture (CAM)

| Advantages of CAM | Disadvantages of CAM |

|---|---|

| Fast and accurate production | Expensive to set up |

| Machines can run constantly on repetitive tasks | Needs a skilled workforce of engineers |

| Good for producing on a mass/flow production line | Downtime required for maintenance |

Can CAD work without CAM

Without CAM, there is no CAD. CAD focuses on the design of a product or part. How it looks, how it functions. CAM focuses on how to make it.

Is a CNC router CAD or CAM

CNC router are often used with two software applications—one to make designs (CAD) and another to translate those designs into a G-code or M-code program of instructions for the machine (CAM) in vertical, horizontal and perpendicular coordinates.

What are 3 advantages of CAD

CAD allows experts to create more accurate design representations. CAD replaced manual design drafting, allowing design development, alteration and optimization. CAD enables engineers to craft more precise designs and manipulate them virtually. CAD software calculates how multiple materials relate.

What are 3 disadvantages of CAD

Disadvantages of CAD:Work can be lost because of the sudden breakdown of computers.Work is prone to viruses.Work could be easily “hacked”Time taking process to know how to operate or run the software.High production or purchasing cost for new systems.Time and cost of training the staff which will work on it.

What are 5 disadvantages of CAD

Disadvantages of CAD:Work can be lost because of the sudden breakdown of computers.Work is prone to viruses.Work could be easily “hacked”Time taking process to know how to operate or run the software.High production or purchasing cost for new systems.Time and cost of training the staff which will work on it.

What are 3 examples of CAD

Popular types of CAD software companies use include SolidWorks, Inventor, Revit, AutoCAD, Civil 3D, MicroStation, CATIA, Creo, and Siemens NX.SolidWorks.Inventor.Revit.AutoCAD.Civil 3D.MicroStation.CATIA.Creo.