Summary of the Article: What Does CAM Mean in Design?

In design, CAM stands for computer-aided manufacturing. It works together with CAD (computer-aided design) to allow machines to create objects directly from computer designs and software. This eliminates the need for manual machine setup by engineers.

Key Points:

1. CAM works in tandem with CAD in the design process.

2. It allows machines to create objects directly from computer designs.

3. CAM eliminates the need for manual machine setup.

4. It uses software to control the manufacturing process.

5. CAM is often programmed to calculate cutting paths for the machine.

6. CAD and CAM can be integrated into a single development tool.

7. CAM ensures high accuracy and precision in manufacturing.

8. SOLIDWORKS CAM is an add-on to SOLIDWORKS CAD.

9. CAD provides digital models that CAM uses to program manufacturing.

10. The integration of CAD and CAM is ideal for seamless workflow.

15 Questions about CAM in Design:

1. What is the difference between CAD and CAM design?

CAD refers to the design or modification of a digital model, while CAM controls the machine used to produce a part.

2. Why do designers use CAM?

CAM is necessary to process the CAD part into machine language (G-Code) and calculate cutting paths.

3. How does CAM relate to computer-aided manufacturing in CAD?

CAM is an integral part of CAD/CAM, which combines design and manufacturing using a single software tool.

4. What role does CAM play in quality?

CAM ensures products are manufactured with a high degree of accuracy and precision.

5. Where else can the acronym CAM stand for?

Outside of design, CAM can also refer to “center attacking midfielders” in sports.

6. Is Solidworks a CAM or CAD software?

SOLIDWORKS is a CAD software, and SOLIDWORKS CAM is an add-on that prepares designs for manufacturability.

7. Why is CAD considered better than CAM?

CAD provides the digital models and information needed for CAM to program manufacturing processes.

8. How does CAD and CAM software interconnect?

In the best-case scenario, CAD and CAM systems can seamlessly interconnect without any data or information loss.

9. Can CAM control the entire manufacturing process?

Yes, CAM software can control various aspects of manufacturing, including cutting paths, tooling, and machine settings.

10. Is CAM only used in specific industries?

No, CAM can be used in various industries that require precision manufacturing, such as aerospace, automotive, and medical.

11. How does CAM improve manufacturing efficiency?

CAM eliminates the need for manual machine setup, reducing the time and effort required in the manufacturing process.

12. Can CAM handle complex designs?

Yes, CAM software can handle complex designs and create precise tool paths to bring them to life.

13. What are some popular CAM software options?

Popular CAM software options include Autodesk Fusion 360, Mastercam, and Siemens NX CAM.

14. What are the benefits of integrating CAD and CAM?

Integration allows for a seamless workflow, reducing errors and improving efficiency in the design-to-manufacturing process.

15. Is CAM suitable for both prototyping and production runs?

Yes, CAM can be used for both prototyping and production, offering flexibility in the manufacturing process.

What does CAM mean in design

computer-aided manufacturing

CAM itself stands for computer-aided manufacturing and usually works in tandem with CAD (computer-aided design) to allow machines to create objects directly from computer designs and software rather than engineers having to set up machines and processes manually.

What is CAD vs CAM design

CAD stands for Computer-Aided Design (in some circles, it can refer synonymously to Computer-Aided Drafting), which refers to the design or modification of a digital model. CAM, on the other hand, is Computer-Aided Manufacturing and controls the machine used to produce a part.

Cached

Why do designers use CAM

CAM comes after CAD designing and is necessary to process the CAD part into a usable computer or machine language. Machine language is often referred to as G-Code. Before converting CAD into machine language, CAM is programmed to calculate the cutting paths.

What does CAM mean in CAD

Computer-aided manufacturing

CAD/CAM refers to the integration of Computer-aided design (CAD) and Computer-aided manufacturing (CAM). CAD/CAM software is used to design and manufacture prototypes, finished products, and production runs of products using a single development tool.

What does CAM mean in quality

Computer-aided manufacturing (CAM) is a type of manufacturing method that uses computer software and automatable machinery to create products with a high degree of accuracy and precision.

Where does CAM stand for

center attacking midfielders

Great center attacking midfielders are extremely creative, they're able to drive at the defensive unit and create something out of nothing. Creativity mixed with discipline means that the CAM can not only dictate how a game goes but is also capable of producing some magic on their own.

Is Solidworks a CAM or CAD

SOLIDWORKS CAM is an add-on to all versions of SOLIDWORKS CAD that lets you prepare your designs for manufacturability earlier in the development cycle.

Why is CAD better than CAM

CAD provides the information-dense digital models that a CAM system needs to program manufacturing. CAM writes intuitive G-code that in turn makes CAD models real. In the best-case scenario, the CAD and CAM software systems can interconnect seamlessly, with no lost data or glitches.

What are examples of CAM

Complementary and alternative medicine includes practices such as massage, acupuncture, tai chi, and drinking green tea. Integrative medicine is an approach to medical care that combines conventional medicine with CAM practices that have shown through science to be safe and effective.

What are 3 disadvantages of CAM

Disadvantages of CAM are:Requires specialist training.Software and machinery costs are expensive.Workers could potentially loose employment due to machines replacing them.

What is an example of CAM

Complementary and alternative medicine includes practices such as massage, acupuncture, tai chi, and drinking green tea.

What is CAM and CAD example

Examples of CAD software include AutoCAD, Autodesk Inventor, CATIA, and Solid Works. Examples of CAM software include Work NC, Siemens NX, Power MILL, and Solid CAM.

What does CAM stand for in architecture

August 3, 2022 Don Catalano. Operating expenses (OpEx) are one of the most significant costs of your commercial property's total cost of occupancy.

What is a CAM example

A common example is the camshaft of an automobile, which takes the rotary motion of the engine and converts it into the reciprocating motion necessary to operate the intake and exhaust valves of the cylinders.

Is AutoCAD a CAM software

CAD and CAM are different. CAD helps designers create digital representations called 3D models while CAM helps write code to drive CNC machines that create physical parts.

Is AutoCAD a CAD CAM software

CAD stands for Computer-Aided Design and CAM stands for Computer-Aided Manufacturing, both of which are used to make things. CAD/CAM software is used to design and manufacture prototypes, finished products and production runs of products.

What is CAM advantages and disadvantages

Computer aided manufacture (CAM)

| Advantages of CAM | Disadvantages of CAM |

|---|---|

| Machines can run constantly on repetitive tasks | Needs a skilled workforce of engineers |

| Good for producing on a mass/flow production line | Downtime required for maintenance |

| Less material wastage | Computers and machines can fail |

What is the most common CAM

Which CAM therapies are the most popularRelaxation techniques.Prayer/spiritual practice.Acupuncture.Yoga.Herbal therapies.Special diet programs.Energy healing.Naturopathy.

What is a good definition of CAM

Complementary and alternative medicine includes practices such as massage, acupuncture, tai chi, and drinking green tea. Credit: iStock. Complementary and alternative medicine (CAM) is the term for medical products and practices that are not part of standard medical care.

What are 2 examples of CAM

What are the different types of CAMAcupuncture.Ayurveda.Homeopathy.Naturopathy.Chinese or Oriental medicine.

What are the pros and cons of CAM

Computer aided manufacture (CAM)

| Advantages of CAM | Disadvantages of CAM |

|---|---|

| Machines can run constantly on repetitive tasks | Needs a skilled workforce of engineers |

| Good for producing on a mass/flow production line | Downtime required for maintenance |

| Less material wastage | Computers and machines can fail |

What are 3 examples of CAM

What are the different types of CAMAcupuncture.Ayurveda.Homeopathy.Naturopathy.Chinese or Oriental medicine.

What is the most common cam

Which CAM therapies are the most popularRelaxation techniques.Prayer/spiritual practice.Acupuncture.Yoga.Herbal therapies.Special diet programs.Energy healing.Naturopathy.

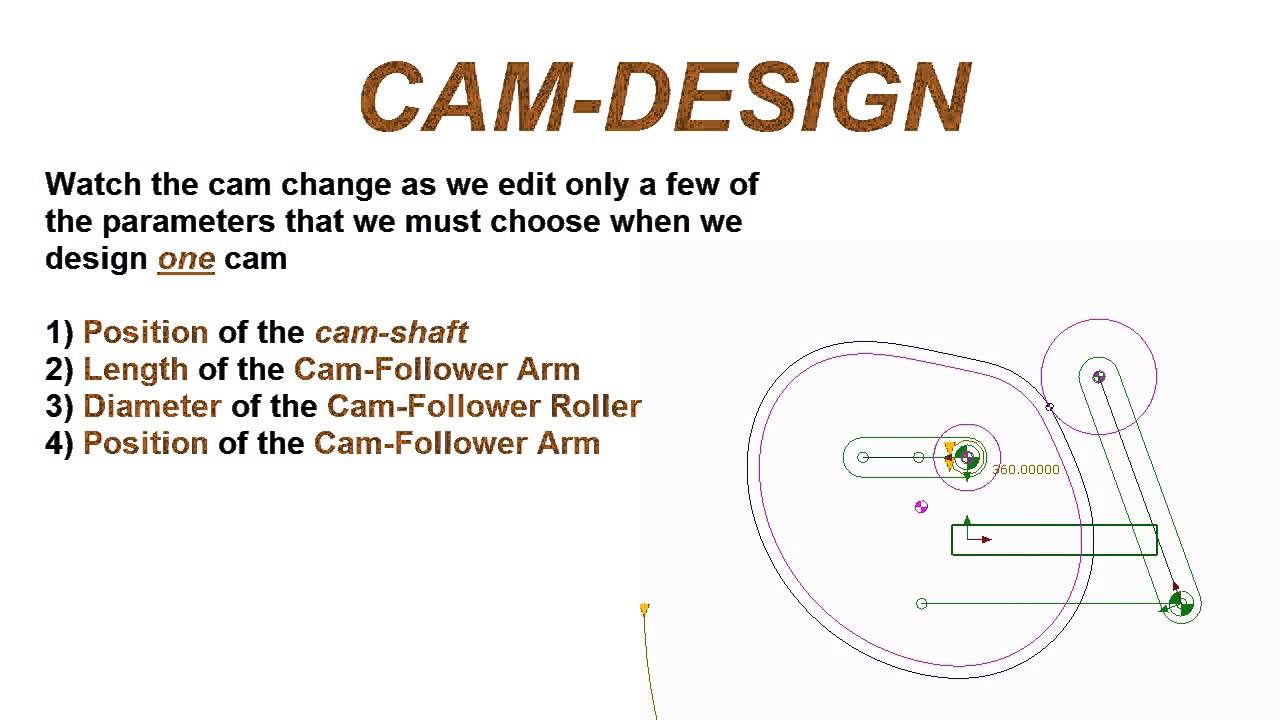

What is CAM in engineering drawing

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion. It is often a part of a rotating wheel (e.g. an eccentric wheel) or shaft (e.g. a cylinder with an irregular shape) that strikes a lever at one or more points on its circular path.

What are 3 examples of cam

What are the different types of CAMAcupuncture.Ayurveda.Homeopathy.Naturopathy.Chinese or Oriental medicine.