art sensors include high initial costs, complexity of integration with existing systems, potential security vulnerabilities, and the need for regular updates and maintenance. Additionally, smart sensors may require specialized training for users and can be limited in terms of compatibility with older technology.[/wpremark]

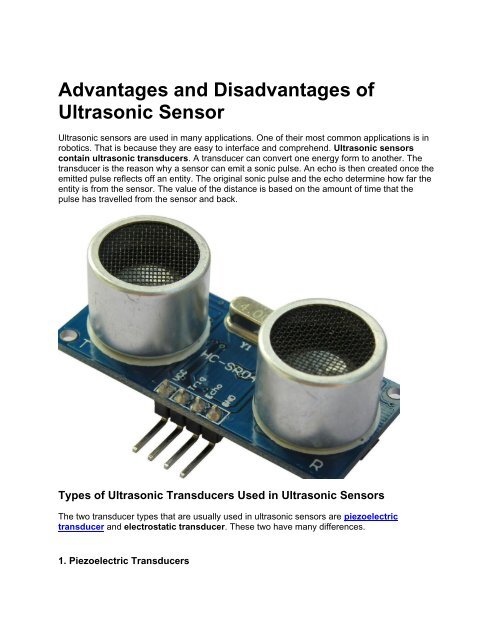

How do ultrasonic sensors work Ultrasonic sensors work by emitting high-frequency sound waves and measuring the time it takes for the sound waves to bounce back after hitting an object. By calculating the time it takes for the sound waves to return, the sensor can determine the distance between itself and the object.

What are the limitations of ultrasonic sensors Ultrasonic sensors have some limitations, including the inability to detect certain materials that absorb or reflect sound waves, such as soft or porous objects. Additionally, ultrasonic sensors may not perform well in environments with excessive noise or strong air currents, which can interfere with the accuracy of the measurements.

Can ultrasonic sensors detect glass Ultrasonic sensors can detect glass, as long as the glass surface is smooth and reflects sound waves. However, if the glass is frosted, textured, or coated with a material that absorbs sound, the ultrasonic sensor may not be able to detect it accurately.

What are the benefits of using sensor technology Sensor technology offers numerous benefits, including improved efficiency, increased accuracy, real-time monitoring, predictive maintenance, and enhanced safety. Sensors can provide valuable data that helps optimize processes, reduce costs, and minimize downtime.

How do distance sensors work Distance sensors work by emitting a beam of light or sound and measuring the time it takes for the beam to bounce back after hitting an object. By calculating the time it takes for the beam to return, the sensor can determine the distance between itself and the object.

What is the lifespan of a sensor The lifespan of a sensor can vary depending on various factors, including the type of sensor, its usage conditions, and the quality of the sensor itself. Generally, sensors are designed to have a lifespan ranging from a few years to several decades, but this can be shorter if the sensor is exposed to harsh environments or undergoes excessive wear and tear.

How can sensor failure be prevented Sensor failure can be prevented by implementing proper maintenance and calibration procedures, ensuring that the sensor is installed correctly and in an appropriate location, and regularly checking for any signs of damage or deterioration. Additionally, using sensors that are specifically designed for the intended application and environment can help improve reliability and longevity.

What are the different types of sensors There are various types of sensors available, including proximity sensors, temperature sensors, pressure sensors, motion sensors, light sensors, and many more. Each type of sensor is designed to detect and measure different physical or environmental parameters.

Can sensors be used in extreme temperatures Yes, there are sensors specifically designed to withstand extreme temperatures, both high and low. These sensors are built with materials and components that can operate reliably in harsh environments, including those with extremely high or low temperatures.

How do sensors improve safety Sensors play a critical role in improving safety by detecting and alerting to potential hazards or abnormal conditions. For example, smoke detectors use sensors to detect the presence of smoke, while motion sensors can trigger alarms or activate security systems when unauthorized movement is detected. Sensors can also be used to monitor and control industrial processes, ensuring that safety protocols are followed and preventing accidents or equipment failures.

How do sensors impact energy efficiency Sensors can significantly impact energy efficiency by enabling smart systems that automatically adjust or optimize energy consumption based on real-time data. For example, occupancy sensors can control lighting or HVAC systems in buildings, ensuring that energy is only used when needed. Similarly, sensors in industrial settings can monitor energy usage and identify areas for improvement, leading to more efficient operations and reduced energy waste.

Can sensors be used in medical applications Yes, sensors are widely used in medical applications for various purposes, such as monitoring vital signs, detecting abnormalities, and delivering targeted therapies. Examples include heart rate monitors, blood glucose meters, pulse oximeters, and imaging devices like X-rays and MRI scanners.

What should I avoid with ultrasonic level sensors

Weather: Ice, snow, dust, mud, and other environmental material buildup can block the sensor face, which can prevent the ultrasonic soundwaves from being transmitted or received. Additionally, the ingress of contaminants, such as water, can affect sensor function.

What is the main disadvantage of sensor

In conclusion, sensors are powerful devices that have many advantages, such as providing real-time data, high precision, and working in harsh environments. However, they also have some disadvantages, such as high costs, susceptibility to interference and damage, and limited lifespan.

Why do ultrasonic sensors fail

Poor ultrasonic level sensor mounting location

Mounting too close to potential unwanted targets, such as pipes, fill streams or even tank walls, if they aren't smooth, can cause false or unstable readings.

What are the pros and cons of distance sensors

The pros of using photoelectric distance measurement sensors are the range, accuracy, repeatability, options, and cost. The main con for using photoelectric sensors for distance measurement is that they are affected by dust and water, so it is not recommended to use them in a dirty environment.

What are two disadvantages of ultrasonic testing

Disadvantages of Ultrasonic Testing Techniques:Training is more extensive than other methods.More expensive than other methods.Difficult to use on thin materials.Part Geometry can cause complications.Needs relatively smooth surface to couple transducer.

How reliable is ultrasonic sensor

For example, an ultrasonic water level sensor reading a full-scale range of 12 feet or 144 inches will have an accuracy of ±0.144 inches (at ambient temperature and controlled conditions). The same sensor reading a distance of 75 inches will have an accuracy of ±0.075 inches.

What are problems for sensor

Dust, other contaminants, vibrations, shocks and exposure to high temperatures all have a shortening effect on the average lifespan of a sensor, so it is important to look for a solution that overcomes these problems by design, rather than just accepting frequent sensor failure and replacement as part and parcel of …

What are the disadvantages of smart sensors

Application disadvantages of smart sensors:R&D time and costs are required.The production process is more complicated.Maintenance costs are high.Power consumption considerations.If connected to the Internet, network stability needs to be considered.

Do ultrasonic sensors work in the dark

Can be used in dark environments. Unlike proximity sensors using light or cameras, dark environments have no effect on an ultrasonic sensor's detection ability.

Which is better IR sensor or ultrasonic sensor

Ultrasonic sensors work using sound waves, detecting obstacles is not affected by as many factors. If reliability is an important factor in your sensor selection, ultrasonic sensors are more reliable than IR sensors. If you're willing to compromise reliability for cost, infrared sensors are ideal for your application.

What are the hazards of ultrasonic testing

There are no potential health hazards associated with ultrasonic testing, unlike radiography. When a test has been properly set up, results are highly repeatable and reliable.

What is the reliability of ultrasonic sensor

The more accurate ultrasonic sensors can achieve 0.1 – 0.2% of the detected range under perfectly controlled conditions, and most good ultrasonic sensors can generally achieve between 1% and 3% accuracy.

What is a better sensor than ultrasonic sensor

Ultrasonic sensors work using sound waves, detecting obstacles is not affected by as many factors. If reliability is an important factor in your sensor selection, ultrasonic sensors are more reliable than IR sensors. If you're willing to compromise reliability for cost, infrared sensors are ideal for your application.

How far can ultrasonic sensor detect

They DO NOT measure farther than about 70 feet (21 meters). They DO NOT measure at very high repetition rates. Due to speed of sound limitations the fastest rate is 200 Hz at a max distance of about 24 inches. They DO NOT work as accurately in vapor environments that change the speed of sound from that of air.

What is the most common cause of sensor failure

Cable break / lead breakage, broken connectors and damaged cable insulation – many of these failure causes and sources of errors in sensors can be traced back to mechanical failure of qualitatively inferior components.

What causes the sensor to break easily

The number one reason sensors fail is physical damage. Sensors operate in a harsh environment of extreme temperatures and vibration. These forces can damage transmission coils, pressure and temperature sensors. Another reason sensors fail is due to damage during removal and installation.

What are the advantages and disadvantages of smart sensors

1) In wired smart sensors, complexity is much higher as a consequence the cost is also high. 2) Required use of predefined embedded function during the design of the smart sensor. 3) It requires both actuators and sensors. 4) Sensor calibration has to be managed by an external processor.

Can ultrasonic go through walls

Ultrasonic waves behave more like light than sound. For example, music from your stereo can fill your entire house. Ultrasound cannot penetrate solid surfaces (walls, floors, ceilings) or travel around corners.

Does ultrasonic go through windows

Ultrasonic sound waves do not penetrate solid objects well. These include items such as: Glass doors and windows.

How accurate are ultrasonic sensors

With an ultrasonic sensor, an accuracy of up to 1% of the set measuring range can be achieved. This means that an object can be detected with an accuracy of 1 mm at a distance of 10 cm. In order for an ultrasonic sensor to work reliably, the sound is emitted at a fixed frequency.

Are ultrasonic sensors safe for humans

Can ultrasonic sensors be used to protect the life or safety of people NO – DO NOT USE any ultrasonic sensor as a primary safety device to detect and protect people!

What is the lifespan of ultrasonic sensor

The MTBF of the MaxSonar product line is 232,896 hours, with a 90% confidence, for products operated at 45°C or less. Because no failures were observed during our testing, we believe that the values in this report can be taken as a conservative estimate of product lifetime.

What can replace ultrasonic sensor

Instead of using sound waves, however, optical technology uses LEDs to emit light waves and detect the time of flight, which can then convert based on the speed of light principle. The speed of light is much faster than the speed of sound, therefore optical-based sensing is faster than ultrasonic.

Can ultrasonic sensors go through walls

Ultrasonic waves behave more like light than sound. For example, music from your stereo can fill your entire house. Ultrasound cannot penetrate solid surfaces (walls, floors, ceilings) or travel around corners.

Can ultrasonic sensor see through walls

1. Ultrasonic can penetrate walls but would probably need an amplified signal to make it through a door and bounce off the opposite wall (maybe a lobby or hallway wall) and then back to the receiver