construction workplaces, and six feet in shipyards. OSHA’s fall protection standard, 29 CFR 1926.501, sets forth requirements for fall protection in construction, including the use of guardrail systems, safety net systems, and personal fall arrest systems.[/wpremark]

What is the most common cause of falls from height The most common cause of falls from height is improper use or lack of use of fall protection equipment. In many cases, workers may not use the equipment provided or may use it incorrectly. It is crucial for employers to provide proper training and ensure that workers understand the importance of using fall protection equipment correctly.

What is the importance of fall protection Fall protection is of utmost importance in any industry where employees work at heights. Falls from heights can result in serious injuries or even death. By implementing proper fall protection measures, employers can ensure the safety and well-being of their employees and prevent accidents and fatalities.

What is the most effective fall protection system The most effective fall protection system depends on the specific task and circumstances. In general, a personal fall arrest system is considered one of the most effective systems as it provides direct protection to the individual worker. However, other systems such as guardrail systems and safety net systems may also be effective depending on the situation.

What are the risks of working at heights Working at heights poses several risks, including the risk of falls, which can result in serious injuries or death. Other risks include being struck by falling objects, electrocution, and getting caught in or between hazards. It is essential for workers to be properly trained and equipped with the necessary fall protection systems to mitigate these risks.

What are some common fall protection hazards Some common fall protection hazards include unprotected edges, improper use or lack of use of fall protection equipment, unstable work surfaces, and tripping hazards. It is crucial for employers to identify these hazards and implement measures to control and mitigate the risks associated with them.

What is the purpose of a safety net system A safety net system is designed to catch a worker in the event of a fall. It acts as a secondary means of fall protection and can help prevent serious injuries or fatalities. Safety net systems are typically installed underneath elevated work areas and must be properly installed and inspected to ensure their effectiveness.

What is the maximum permitted free fall distance The maximum permitted free fall distance in a personal fall arrest system is six feet. When a fall occurs, the lanyard or lifeline should be designed and positioned in such a way that it limits the free fall distance to six feet or less. This helps reduce the impact force on the worker’s body and prevents serious injuries.

What are the 4 components of a fall protection system

Personal Fall Arrest Systems. “Personal fall arrest system” means a system used to arrest an employee in a fall from a working level. It consists of an anchorage, connectors, a body belt or body harness and may include a lanyard, deceleration device, lifeline, or suitable combinations of these.

What are the methods of fall protection

Generally, fall protection can be provided through the use of guardrail systems, safety net systems, or personal fall arrest systems. OSHA refers to these systems as conventional fall protection. Other systems and methods of fall protection may be used when performing certain activities.

Cached

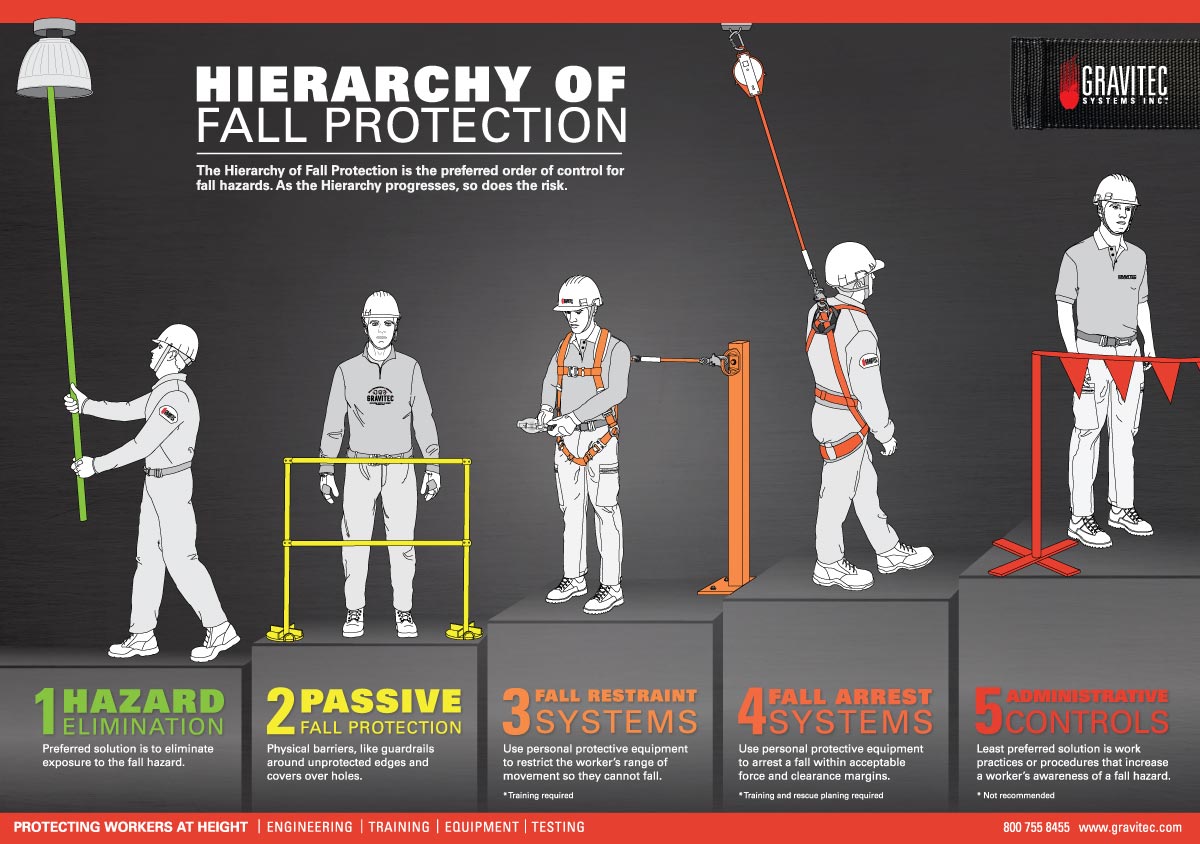

What is the correct order of fall protection

The hierarchy of fall hazard control includes: elimination of fall hazards, prevention (Engineering Controls) of falls, and control (Training and PPE) of falls.

What are the 4 categories of fall hazard

Dubbed the “Fatal Four” by OSHA, they include falls, electrocutions, being struck by objects, and getting caught in or between hazards. In 2016, the “Fatal Four” were responsible for 63.7% of all construction worker deaths. Falls are the leading cause of construction worker deaths.

What are three fall protection systems

While there are a series of questions you can ask yourself to assess the safety of your team while working at height, there are three different types of fall protection systems: elimination, prevention, and arrest.

What are the ABCS of fall protection

For years, folks in the fall protection industry have preached the ABC's of personal fall arrest systems: Anchorage, Body Support, and Connecting Devices. This is a great start because the approach has us thinking systematically.

What are 3 fall prevention methods

Fall prevention: Simple tips to prevent fallsMake an appointment with your health care provider. Start by making an appointment with your health care provider.Keep moving. Physical activity can go a long way toward fall prevention.Wear sensible shoes.Remove home hazards.Light up your living space.Use assistive devices.

What is the OSHA standard for fall protection

OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations.

What is the OSHA rule for fall protection

OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations.

What is the OSHA final rule for fall protection

Fall protection flexibility (§1910.28(b)).

The final rule allows employers to protect workers from falls by choosing from a range of accepted fall protection systems, including personal fall protection systems.

What are the 5 elements of fall safety

The 5 steps of fall preventionIdentify the risks. There are many potential hazards present when working at heights, particularly pertaining to the risk of falling from an elevated surface.Avoid the risk.Control the risk.Respond to incidents.Maintain risk prevention.

What are the ABCD of fall protection

ABCD stands for: Anchorage, Body Support, Connection and Descent/Rescue. This workflow and combination of safety equipment is essential for jobsite safety when working from heights.

What is the most common fall protection system

On many sites, guardrails are the most common and convenient means of fall protection. Where guardrails cannot be used, workers must use another means of fall protection to prevent a fall. Two basic types of fall protection are travel restraint and fall arrest. Both involve wearing a full-body harness.

What is the 3 step fall prevention process

The intervention is based on the theoretical underpinning that fall prevention in hospitals is a three-step process: (1) assessing fall risk, (2) developing a personalized prevention plan, and (3) executing the plan consistently.

What are 5 ways to prevent falls

Steps to take to prevent fallsStay physically active.Try balance and strength training exercises.Fall-proof your home.Have your eyes and hearing tested.Find out about the side effects of any medicines you take.Get enough sleep.Avoid or limit alcohol.Stand up slowly.

What is the OSHA standard for fall protection in 2023

OSHA says, "When work is performed at least 6 feet (1.6 m) but less than 15 feet (4.6 m) from the roof edge, the employer must ensure each employee is protected from falling by using a guardrail system, safety net system, travel restraint system, or personal fall arrest system.

What is the maximum allowable free-fall distance

6 feet

A free fall may be more than 6 feet (1.8 m) provided the employer can demonstrate the manufacturer designed the system to allow a free fall of more than 6 feet and tested the system to ensure a maximum arresting force of 1,800 pounds (8 kN) is not exceeded.

What are the requirements for fall protection in OSHA 1910

The employer must ensure each employee on a runway or similar walkway is protected from falling 4 feet (1.2 m) or more to a lower level by a guardrail system. Each employee is provided with and uses a personal fall arrest system or travel restraint system.

What is OSHA New fall protection standard

Unprotected sides and edges. Each employee on a walking/working surface (horizontal and vertical surface) with an unprotected side or edge which is 6 feet (1.8 m) or more above a lower level shall be protected from falling by the use of guardrail systems, safety net systems, or personal fall arrest systems.

What is the maximum allowable free fall distance

6 feet

A free fall may be more than 6 feet (1.8 m) provided the employer can demonstrate the manufacturer designed the system to allow a free fall of more than 6 feet and tested the system to ensure a maximum arresting force of 1,800 pounds (8 kN) is not exceeded.

What are 3 guidelines for preventing falls

Steps to take to prevent fallsStay physically active.Try balance and strength training exercises.Fall-proof your home.Have your eyes and hearing tested.Find out about the side effects of any medicines you take.Get enough sleep.Avoid or limit alcohol.Stand up slowly.

What are the 5 key steps in a falls risk assessment

You can do it yourself or appoint a competent person to help you.Identify hazards.Assess the risks.Control the risks.Record your findings.Review the controls.

What is the OSHA code for fall protection

1926.501 – Duty to have fall protection. Occupational Safety and Health Administration.

What are the ABCS of full protection

The 'ABC's of fall protection' is a common way of referring to the three key components of a personal fall arrest solution (PFAS) – Anchorage, Body wear and Connecting device – and is now relatively well known in the safety industry.

What is the OSHA standard for fall protection systems

OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations.