Summary: CAM Systems

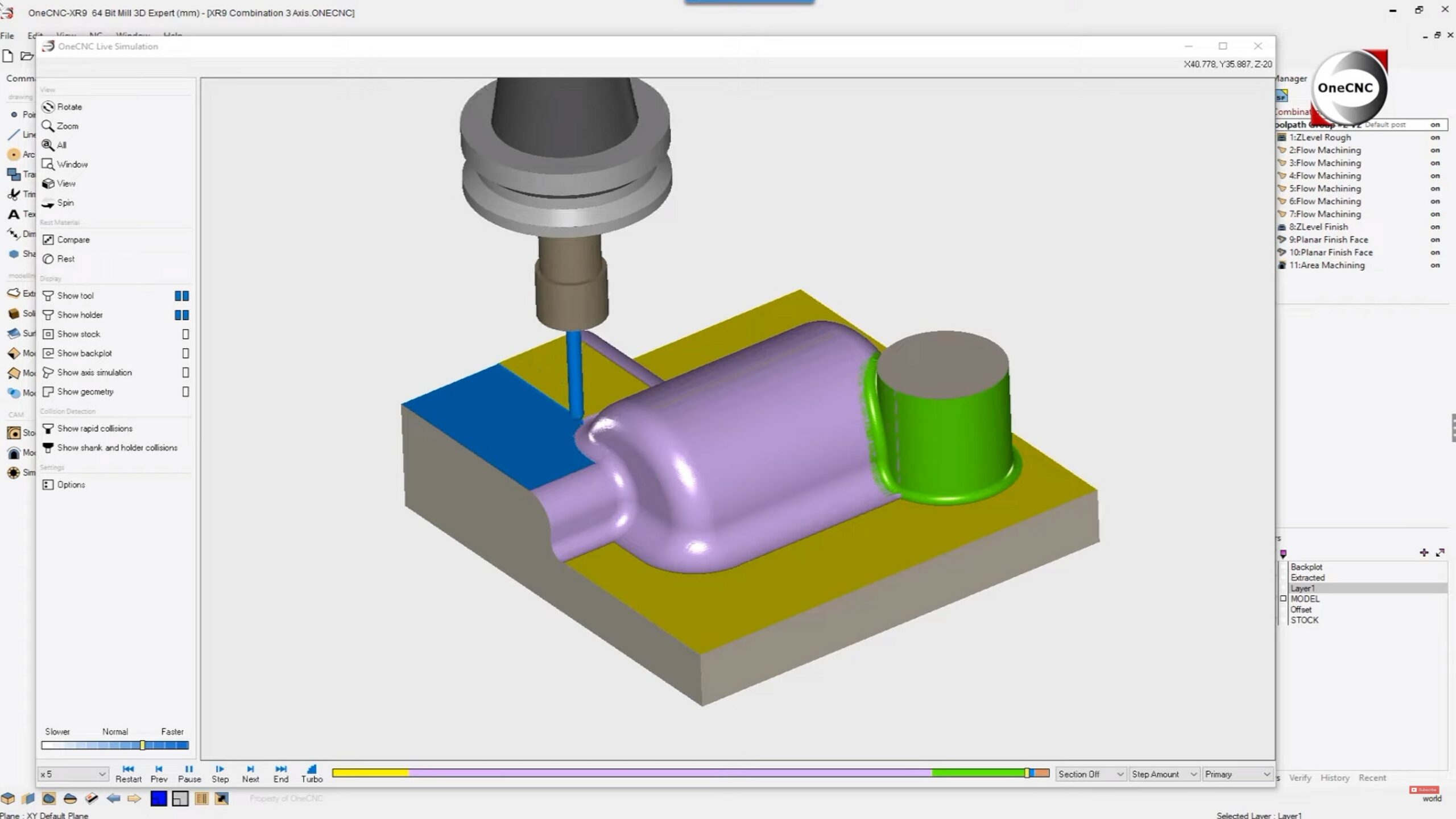

CAM (Computer-Aided Manufacturing) systems are used in various industries, such as plasma cutters, laser cutters, milling machines, and Electrical Discharge Machines (EDM). These systems allow for high production speed and precision in creating intricate parts, including circuit boards. CAD (Computer-Aided Design) and CAM are different but complementary. CAD helps designers create 3D digital models, while CAM software generates the code to operate CNC (Computer Numerical Control) machines for physical part production.

CAM is also an abbreviation for “camshaft,” an engine part responsible for opening and closing valves in combustion chambers. It ensures the intake and exhaust of the air-fuel mixture. Different types of CAM practices include acupuncture, Ayurveda, homeopathy, naturopathy, and Chinese or Oriental medicine.

The most commonly used type of CAM is the cam plate, which is cut from a piece of flat metal or plate, allowing the follower to move perpendicular to the camshaft’s axis of rotation. While CAM systems bring numerous advantages, including high production speed and accuracy, there are also several disadvantages. These include the requirement for specialist training, high software and machinery costs, and potential job displacement as machines replace manual labor.

Urban planners utilize CAD/CAM software to design and plan urban infrastructure, such as bridges, parks, office complexes, and more. SOLIDWORKS CAM, for example, is an add-on to SOLIDWORKS CAD that enables designers to ensure manufacturability in the early stages of development.

Key Points:

- Various examples of CAM systems include plasma cutters, laser cutters, milling machines, and Electrical Discharge Machines (EDM).

- CAM enables high-speed machine tool paths and precision in manufacturing parts.

- CAD and CAM are different but complementary. CAD helps create 3D digital models, while CAM generates CNC machine code.

- CAM can refer to camshafts, engine parts responsible for opening and closing valves in combustion chambers.

- Cam plate is the most common type of cam, allowing movement perpendicular to the camshaft’s axis of rotation.

- Disadvantages of CAM include the need for specialized training, high software and machinery costs, and potential job displacement.

- Urban planners utilize CAD/CAM software for designing urban infrastructure.

- SOLIDWORKS CAM is an add-on to SOLIDWORKS CAD for early manufacturability preparation.

Questions and Answers:

- What is an example of a CAM system?

Plasma cutters, laser cutters, milling machines, and Electrical Discharge Machines (EDM) are examples of CAM systems. - What does CAM allow you to do?

CAM allows for high-speed machine tool paths, leading to faster part production. It also enables precision, even allowing for the creation of intricate circuit boards. - Is AutoCAD a CAM software?

No, AutoCAD is primarily CAD software used for creating digital 3D models, while CAM software generates code for CNC machines. - What is a CAM and what is it used for?

CAM can refer to a camshaft, which opens and closes valves in combustion chambers to control the air-fuel mixture. It is an essential part of every engine. The primary function of the camshaft is to regulate the valve operation. - What are three examples of CAM practices?

Acupuncture, Ayurveda, and homeopathy are examples of CAM practices. These practices focus on holistic approaches to healthcare. - What is the most common type of cam?

The cam plate, also known as a disc cam or radial cam, is the most commonly used type of cam. It is cut from a piece of flat metal and enables the follower to move in a plane perpendicular to the camshaft’s axis of rotation. - What are five disadvantages of CAM?

Some disadvantages of CAM include the need for specialist training, high costs of software and machinery, and the potential for job displacement as machines replace manual labor. - Who uses CAM software?

Urban planners utilize CAD/CAM software to design and plan various urban infrastructure projects, such as bridges, parks, industrial units, and office complexes. - Is Solidworks a CAM or CAD?

SOLIDWORKS is primarily CAD software, but it also offers SOLIDWORKS CAM as an add-on. This allows designers to prepare their designs for manufacturability earlier in the development cycle.

What is an example of a CAM system

Plasma cutters. Laser cutters. Milling machines. Electrical Discharge Machines (EDM)

What does CAM allow you to do

High production speed: CAM allows for high-speed machine tool paths, making it possible to produce parts faster. Precision: Parts can be intricate. Even circuit boards are possible when designs are prepared with CAM software.

Cached

Is Autocad a CAM software

CAD and CAM are different. CAD helps designers create digital representations called 3D models while CAM helps write code to drive CNC machines that create physical parts.

What is a CAM and what is it used for

Cam is short for camshaft, the engine part that opens and closes the valves to let the air-fuel mixture in and out of combustion chambers. Every engine manufactured today has, if not one, then at least two or more installed. The camshaft's primary function is to close and open the valves.

What are 3 examples of CAM

What are the different types of CAMAcupuncture.Ayurveda.Homeopathy.Naturopathy.Chinese or Oriental medicine.

What is the most common type of CAM

The most commonly used cam is the cam plate (also known as disc cam or radial cam) which is cut out of a piece of flat metal or plate. Here, the follower moves in a plane perpendicular to the axis of rotation of the camshaft.

What are 5 disadvantages of CAM

Disadvantages of CAM are:Requires specialist training.Software and machinery costs are expensive.Workers could potentially loose employment due to machines replacing them.

Who uses CAM software

Urban planners use CAD / CAM software to plan urban infrastructure including bridges, parks, industrial units, office complexes, and more.

Is Solidworks a CAM or CAD

SOLIDWORKS CAM is an add-on to all versions of SOLIDWORKS CAD that lets you prepare your designs for manufacturability earlier in the development cycle.

What is difference between CAM and CAD

CAD is the use of computers in order to develop, modify and analyse the design. CAM is the use of computer software in order to handle machine tools used in the manufacturing of modules. It is also called Computer-Aided Drafting. It is also called Computer-Aided Modelling.

What are 3 benefits of cam

The benefits of CAMGreater speed in producing components.Greater accuracy and consistency, with each component or finished product exactly the same.Greater efficiency as computer controlled machines do not need to take breaks.High sophistication in terms of following complex patterns like tracks on circuit boards.

How much HP does a comp cam add

LQ4 Cam vs Comp Cam

After installation of the Comp cam, the power output jumped to 550.3 hp and 512 lb-ft of torque. The cam swap improved the power output by more than 100 hp, but the gains were even greater out near 6,500 rpm.

What is the most common CAM used

Which CAM therapies are the most popularRelaxation techniques.Prayer/spiritual practice.Acupuncture.Yoga.Herbal therapies.Special diet programs.Energy healing.Naturopathy.

Which is the best cam software

Top 10 Computer-Aided Manufacturing (CAM) SoftwareSolid Edge.SOLIDWORKS.NX CAM.Fusion 360.GibbsCAM.Mastercam.FeatureCAM.CAMWorks.

What are 3 of the most common cam therapies

Some CAM therapies have undergone careful evaluation and have been found to be generally safe and effective. These include acupuncture, yoga, and meditation to name a few.

Who typically uses cam

The evidence suggests that people who use CAM tend to be female, of middle age and have more education. In terms of their health, CAM users tend to have more than one medical condition, but might not be more likely than non-users to have specific conditions such as cancer or to rate their own general health as poor.

What are the pros and cons of CAM

Computer aided manufacture (CAM)

| Advantages of CAM | Disadvantages of CAM |

|---|---|

| Machines can run constantly on repetitive tasks | Needs a skilled workforce of engineers |

| Good for producing on a mass/flow production line | Downtime required for maintenance |

| Less material wastage | Computers and machines can fail |

What is the difference between AutoCAD and CAM

CAD is used for creating 2D and 3D drawings and models. CAM is to design machining processes through 3D models. It is usually preferred by engineers. It is usually employed by a trained machinist.

What is the difference between CAD and CAM

CAD stands for Computer-Aided Design (in some circles, it can refer synonymously to Computer-Aided Drafting), which refers to the design or modification of a digital model. CAM, on the other hand, is Computer-Aided Manufacturing and controls the machine used to produce a part.

Is Solidworks a CAD or CAM or CAE

SOLIDWORKS is considered one of the best CAD and CAE software available, with a wide range of features that make it fast and effective for both new and experienced designers.

Does camming a car make it faster

Does Camming A Truck Make It Faster In most cases, yes, but it depends on the model of the truck and which custom cam you use. With that said, aftermarket cams are designed for high-end performance, so you can typically expect to experience faster speeds after camming a truck.

Does camming a car make it louder

Yes, it will be louder.

What are the 4 types of CAM

CamsCircular. Circular cams use an off-centre pivot to cause the follower to move up and down.Pear. Pear cams are called this as they have the shape of a pear.Snail or drop. Snail or drop cams have the appearance of a snail shell.Heart-shaped or constant velocity.

Who typically uses CAM

The evidence suggests that people who use CAM tend to be female, of middle age and have more education. In terms of their health, CAM users tend to have more than one medical condition, but might not be more likely than non-users to have specific conditions such as cancer or to rate their own general health as poor.

What is the difference between CAM and CAD software

The most basic difference between the two is that CAD (Computer Aided Design) is used for designing of products using some designing software, whereas CAM (Computer Aided Manufacturing) is a software used to control the machines (like CNC machine) involved in industrial processes.